Workshop Blog January 2023

Another month has passed and surprisingly I have actually managed to make a little progress on the dirt bike build…

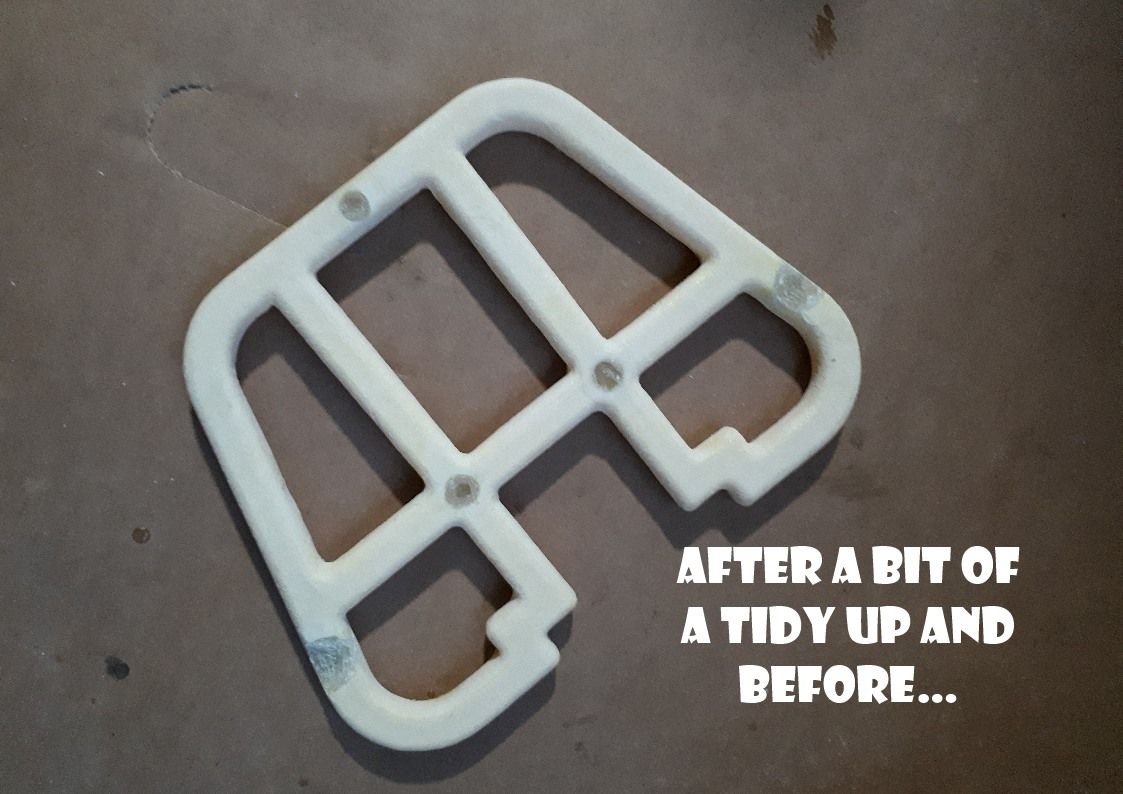

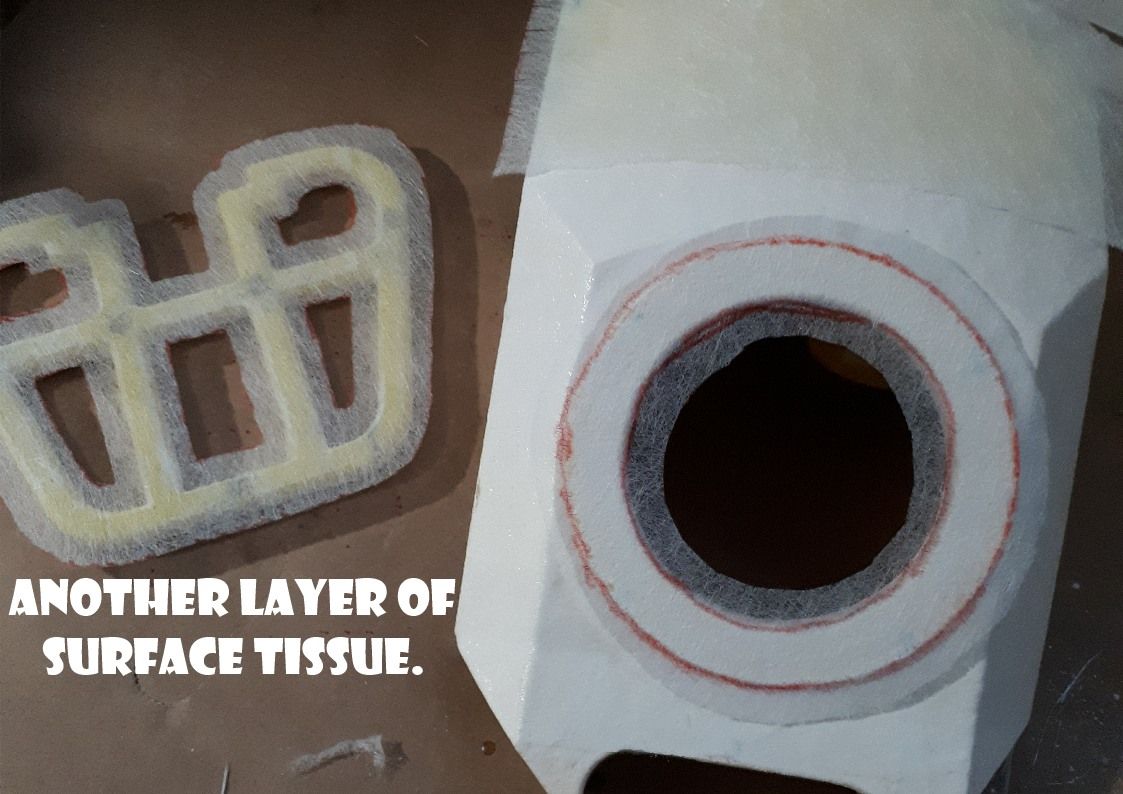

A bit more fibreglass has been added to both the front cowl and the rear rack. I have to admit that at the moment I don’t really have a plan, it’s just suck it and see. Neither of them are looking pretty, but eventually a beautiful swan may emerge from these ugly ducklings. Maybe or maybe not…

The trials bike has also been shown a little love. I’m hoping that finally I’ve cured the leaky exhaust flange by very carefully filing it flat. For a proper belt and braces job, it also has a new gasket and some exhaust assembly paste. Being a trials bike, everything is tightly packed so I also now have a specially ground down allen key to allow me to actually access the bolts!

The bike also got a new inline filter. Kind of scary what heat and petrol will do over time, the banana shaped one used to look exactly like that shiny new one.

Plus, there’s a new toy in the toolbox! I finally purchased a mechanic's stethoscope. This is a Silverline branded version and also the cheapest one that I could find. I put off buying one of these for years as I thought sticking my ear to the end of a long screwdriver was just as good. I can tell you that it isn’t. This is much better.

If you don’t know what one is used for, basically you put your probe at various places around the engine and you can then have a listen to the noise emanating from inside. It’s useful for trying to track down and then take an educated guess at where or what is causing that engine noise that might be bothering you. I tried it on the noisy old GS500. Funnily enough, this engine actually sounds quieter when listened to via the stethoscope. It’s air cooled and I think all those fins tend to amplify any noises that are present. It’s actually quite therapeutic listening to the engine ticking away. Probably not quite so calming if you’re listening to a big end bearing knocking away like a good-un.

The milling machine is now next door, in the garage and not 4 miles away, so I’ve used it to modify the brackets for the front cowl. Nothing major, just a little bit of a trim up to allow the cowl to fit and the clamps not foul the petrol tank on full lock.

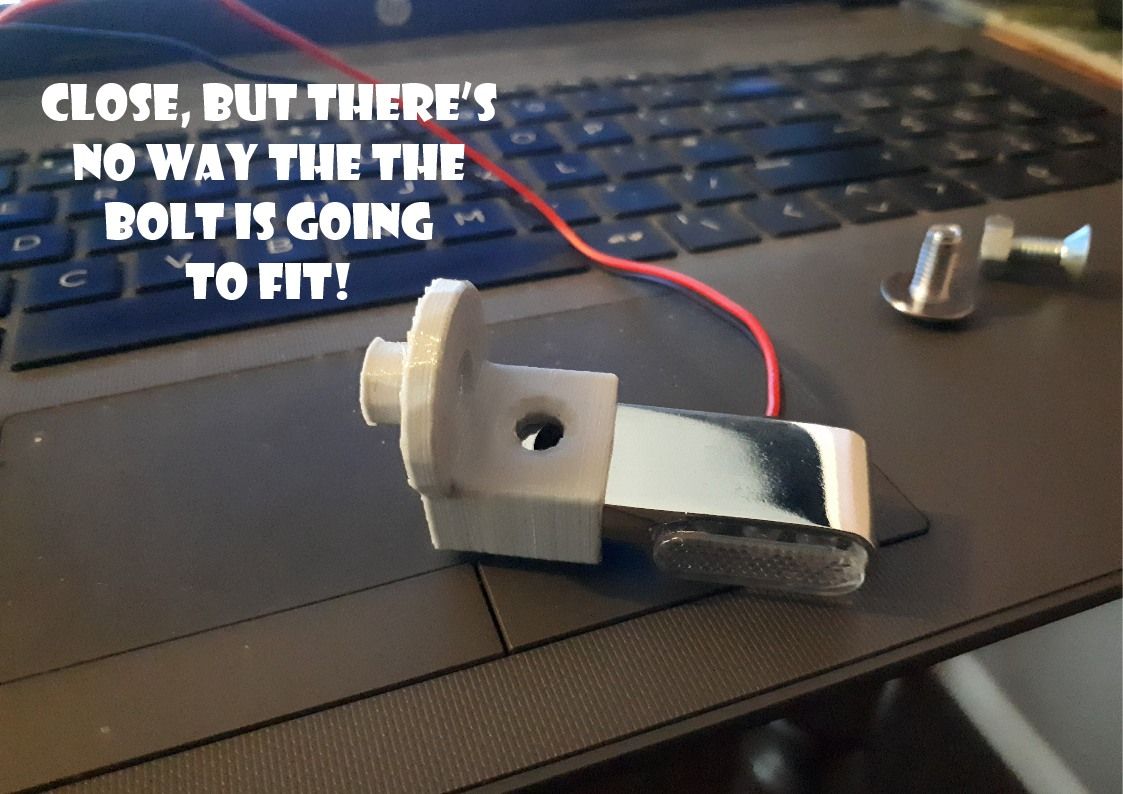

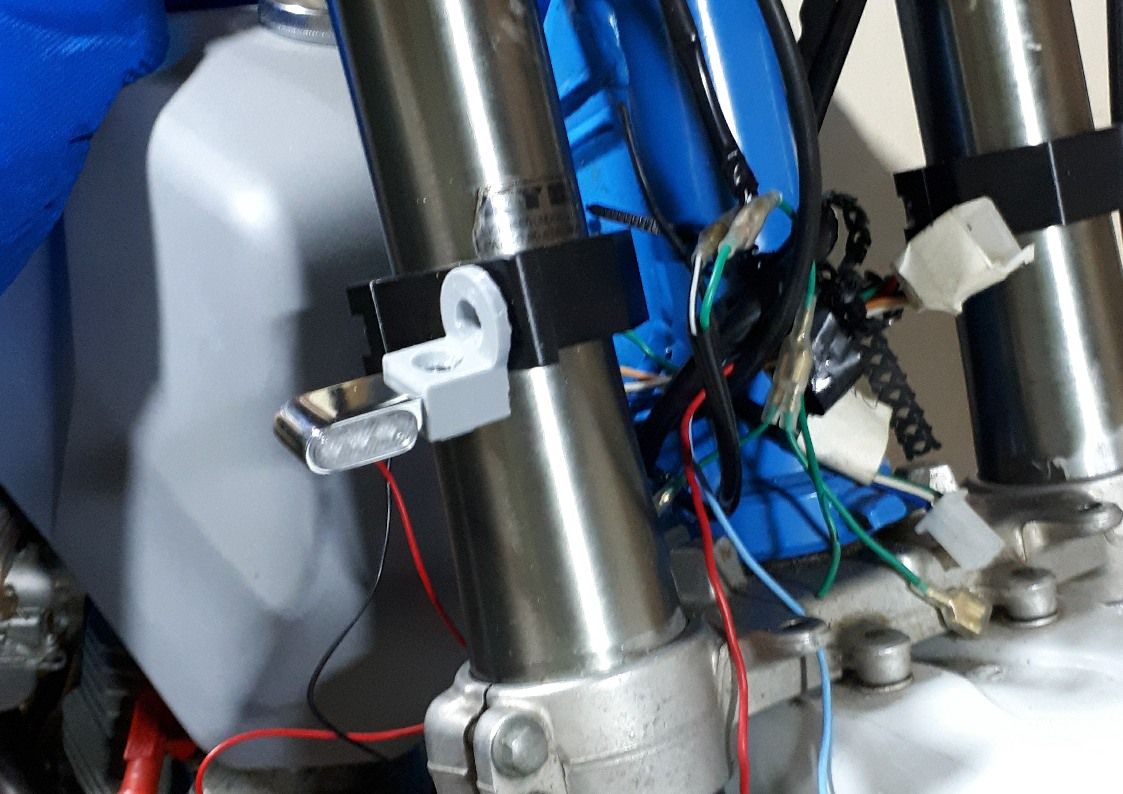

The 3D printer has also been busy, churning out some potential front indicator / headlight cowl mounts and it only took me two goes to get them the right size!