3D printers are great bits of kit, but they can also be incredibly frustrating, today was to be one of those days. I wanted to try some new material that I'd purchased, but after 3 hours, I still hadn't found satisfactory print settings and I could feel my patience starting to slip. So, before I smashed the printer into a thousand little pieces, I gave up with the new material and used the old stuff instead - I still had to wait the best part of 8 hours for it to print...

Not the most interesting week, this week, but the job needs doing...

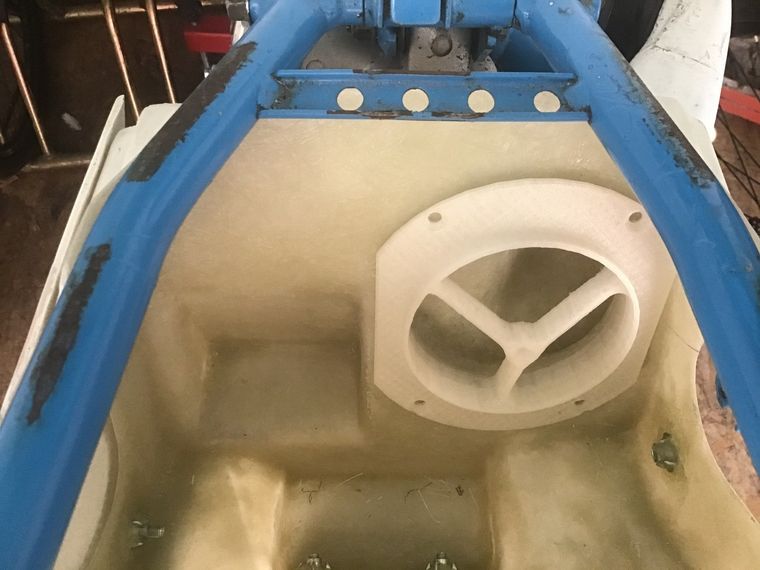

The design of the mudguard means that the mould has to be split (otherwise I'd never get it out!). If I'd thought about it a bit more at the design stage, I'd probably have modified it so that this wasn't necessary, but it's too late now...

The pattern needs to have a split line running the entire length of the mudguard, and so I need to build a fence, ideally using whatever junk I can find laying around. Pressed into service is a length of galvanized wire, bent to the outline of the mudguard and a mouldy bit of 2mm MDF.

After attacking the mdf with saws, flap discs and sandpaper, I manage to make something that almost fits. The (clearly visible) gaps can be filled with moulding wax.

I also needed something to securely support the mudguard for moulding. Two empty moulding resin containers do the job admirably. I knew there was a reason why I hadn't thrown them out.

Being a bit floppy, the 2mm MDF needs reinforcing with some thicker bits of wood. Spring clamps at either end are sufficient to hold everything in place.

Border has been given a couple of coats of paint and the whole thing has had several layers of mould release polish. You can also see the yellow mould wax that has been used to seal the gaps between border and mudguard.

For extra insurance, it's also had a coat of blue PVA mould release.

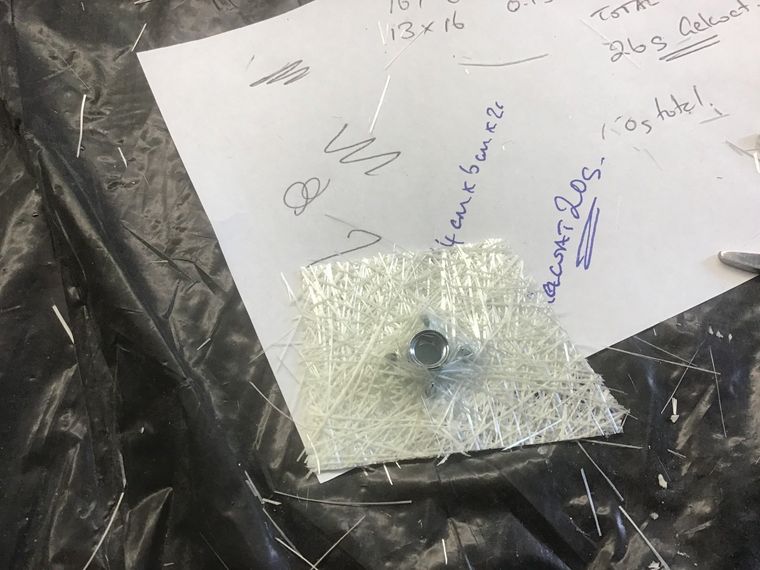

Gel coat is on the first side. By next week's installment, I hope to have the mould finished.