Some time ago, when we were looking at testing switchgear, I mentioned that one of the reasons why you might need to take care when using some of the available Chinese switchgear was because the cable diameters were very small. This article will try to explain why cable diameter matters.

Let’s take a headlight as an example. My headlight bulb is rated at 60W (Watts, a measure of power). Nominally, we’ll take the voltage as being 12V (Volts). When the headlight switch is operated, the circuit is completed, an electrical current will flow and the bulb will illuminate. We can work out just how much current will flow using a bit of mathematics.

This is the relationship:- Power = Volts x Amps (current)

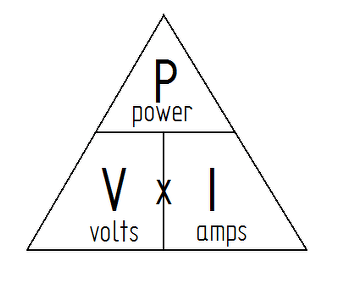

It’s often shown in triangle form to makeit easier to remember and rearrange for the other units.

Let’s take a headlight as an example. My headlight bulb is rated at 60W (Watts, a measure of power). Nominally, we’ll take the voltage as being 12V (Volts). When the headlight switch is operated, the circuit is completed, an electrical current will flow and the bulb will illuminate. We can work out just how much current will flow using a bit of mathematics.

This is the relationship:- Power = Volts x Amps (current)

It’s often shown in triangle form to makeit easier to remember and rearrange for the other units.

I.e.Voltage = Power / Amps

Current = Power / Volts

In the case of the headlight, we know the power (60W) and the voltage (12V) and want to find out the current that will flow. So using the relevant equation, we get:

Current = 60 / 12 = 5 Amps

To safely allow our headlight to work, we need a cable that can carry 5 Amps.

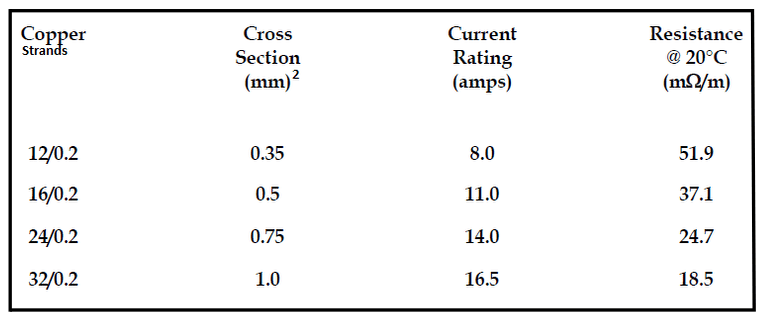

The table below lists the basic cable properties that you need to be interested in. You will want a cable that is flexible (for ease of threading it around the frame and because it is much less susceptible to work hardening and possible breakage when exposed to vibration) so a stranded cable is the one to use.

To safely allow our headlight to work, we need a cable that can carry 5 Amps.

The table below lists the basic cable properties that you need to be interested in. You will want a cable that is flexible (for ease of threading it around the frame and because it is much less susceptible to work hardening and possible breakage when exposed to vibration) so a stranded cable is the one to use.

The second column is the cross-sectional area of the cable. You could calculate this value from the number / size of strands column, but it’s much easier if someone else has done it for you. The third column is the one we’re most interested in, this is the maximum current that the cable can carry continuously. Here you can see that the first cable would be adequate for our needs, with a reasonable amount of spare capacity. It’s always good practice to select a cable with a extra capacity. If you were to use a cable with too low a current rating, everything could start to get a bit hot. If you get pessimistic and select a bigger cable than you really need, then electrically, that’s no problem, but you may pay more for your cable, and the finished wiring loom will be a bit heavier.

The final column, is the resistance of the cable per meter. Because the cable has some resistance, some energy will be lost along it. In practice this means that if you apply 12V at one end of the cable run, by the time it gets to your headlight bulb, you may end up with less than 12V. I’ll spare you details of the calculations, because cable runs on bikes are usually quite short and because, providing the reg / rec is working OK, you’ll probably be running at around 13.5 - 14V anyway. But, if the headlight bulb used in the example was 1 meter away from the battery, then the voltage drop would be around 0.5V. If the voltage drop proves to be excessive, it can be reduced by selecting a cable with a slightly larger cross-section. (Notice how the resistance per meter figure drops as cable cross-section increases.) I’ll go out on a limb and say that providing the cable runs are short, and providing you select a cable cross-section that has a plenty of spare current capacity, you probably won’t have to worry too much about voltage drops.

If you want to read more about selecting a cable, cable materials and voltage drops, I suggest you try the ‘12Volt Planet’ website, particularly their ‘Knowledge Centre’. 12VoltPlanet will also sell you cable. Other suppliers worth a look are ‘kojaycat’ and ‘vehicle wiring products’

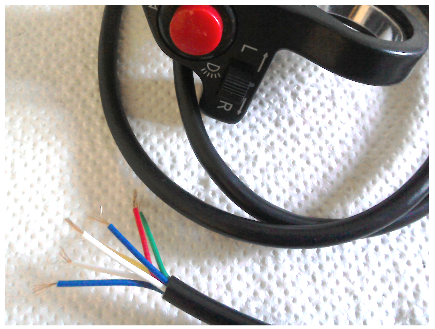

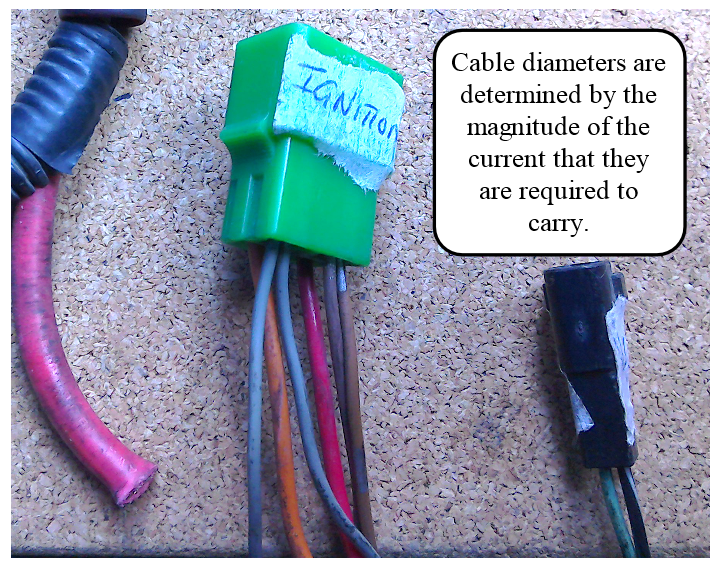

I hope by now you’re starting to understand the importance of the cross-sectional area of the copper part of a cable. If you look at the picture below, you’ll see that cable diameters vary greatly within motorcycle wiring. The largest ones are usually associated with the electric start circuitry. Starter motors draw large currents when trying to turn the engine over.

The final column, is the resistance of the cable per meter. Because the cable has some resistance, some energy will be lost along it. In practice this means that if you apply 12V at one end of the cable run, by the time it gets to your headlight bulb, you may end up with less than 12V. I’ll spare you details of the calculations, because cable runs on bikes are usually quite short and because, providing the reg / rec is working OK, you’ll probably be running at around 13.5 - 14V anyway. But, if the headlight bulb used in the example was 1 meter away from the battery, then the voltage drop would be around 0.5V. If the voltage drop proves to be excessive, it can be reduced by selecting a cable with a slightly larger cross-section. (Notice how the resistance per meter figure drops as cable cross-section increases.) I’ll go out on a limb and say that providing the cable runs are short, and providing you select a cable cross-section that has a plenty of spare current capacity, you probably won’t have to worry too much about voltage drops.

If you want to read more about selecting a cable, cable materials and voltage drops, I suggest you try the ‘12Volt Planet’ website, particularly their ‘Knowledge Centre’. 12VoltPlanet will also sell you cable. Other suppliers worth a look are ‘kojaycat’ and ‘vehicle wiring products’

I hope by now you’re starting to understand the importance of the cross-sectional area of the copper part of a cable. If you look at the picture below, you’ll see that cable diameters vary greatly within motorcycle wiring. The largest ones are usually associated with the electric start circuitry. Starter motors draw large currents when trying to turn the engine over.

Returning to the Chinese switchgear, I tried to count the number of strands and measure their diameter. It wasn’t easy, they’re very tiny and I had to use a jeweller’s loupe to see them clearly. I think there are 12 strands, each 0.09mm in diameter. This gives a cross-sectional area of approximately 0.08 square mm. A bit of searching on the internet suggests that this cable could only handle around 0.7A, way below the 5A the headlight bulb draws. One of the switches is designed to be the headlight switch, clearly it wouldn’t be sensible to connect a 60W load to this tiny cable and you’d also need to question if the switch itself is capable of coping with this level of current. Now it may be possible to use these switches with LED lights rather than conventional bulbs, LEDs have a much lower current requirement, but I haven’t fully researched this. From a quick search on Ebay, the lowest powered LED headlights were quoting a 10W power consumption. That still equates as a 0.8A current requirement. More than this tiny cable should be asked to cope with. If you’re into your electronics, you could always incorporate additional circuitry (relays and the like) to get over this problem, but most of us just want to plug and play.

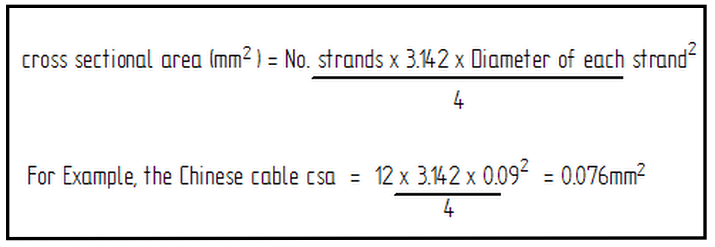

If you need to replace or extend cables in an existing wiring loom and don’t know or can’t estimate the current that is likely to be flowing, then you may need to do what I did with the switchgear wires, namely carefully count how many strands there are and accurately measure their diameter. The maths you then require is shown below. Remember, just measuring the outside diameter of a cable complete with insulation tells you nothing. It’s the copper inside that’s important.