The IBiiS GS500 is (as its name suggests) based on a Suzuki GS500. I picked the GS because it's a fairly simple air-cooled twin, there are lots of them about (a GS500 variant was available from 1989 to 2008!) and they haven't experienced the same price hike that many similar aged bikes have recently been subjected to. I mean, not so long ago you wouldn't have been able to give away an old CX500, 250 Superdream or CG125, but they've suddenly become hot property.

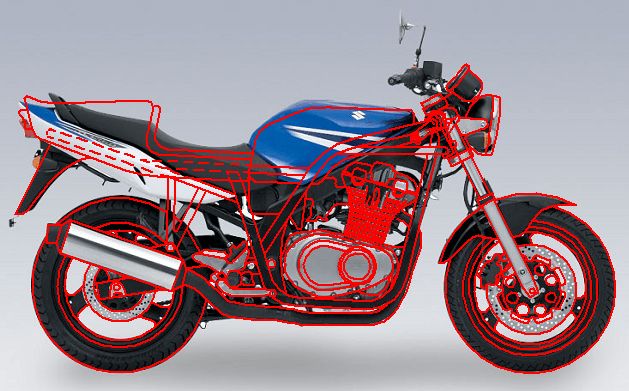

I started with drawing an outline of what I wanted over a picture of the standard bike. This was before I'd even bought a donor bike. You can usually find a good side on picture via the internet. You can scribble over it to your heart's content to get some ideas and it's a lot cheaper to try stuff out on paper first.

I used CAD (if you haven't got a CAD package to use already, you can find some free versions via the internet) which makes it easy to draw lines, change your mind, draw a different line etc. Of course, you could just go old school and print out some pictures to draw over.

From my initial drawings, it became obvious that I would need to be able to bend some tube in order to make the frame. Looking at tube benders online, it was also clear that I couldn't afford to buy a proper tube bender and a donor bike!

I spent some time looking at websites and youtube videos of home built tube benders. The Chopper Builder's Handbook website (see resources section for link) had plans for making a bender, but still relied on buying the dies - and these are expensive on their own - which still made it a pricey undertaking.

In the end I decided to try to machine my own dies, and used the plans from the Chopper Builder's site as a guide to building a bender to suit the type of dies that I the facilities to make.

First step was to decide what tube sizes I intended to use (each tube diameter requires its own die) and what bend radius I was going to use. (In these types of bender, the bend radius is dictated by the radius of the die.)

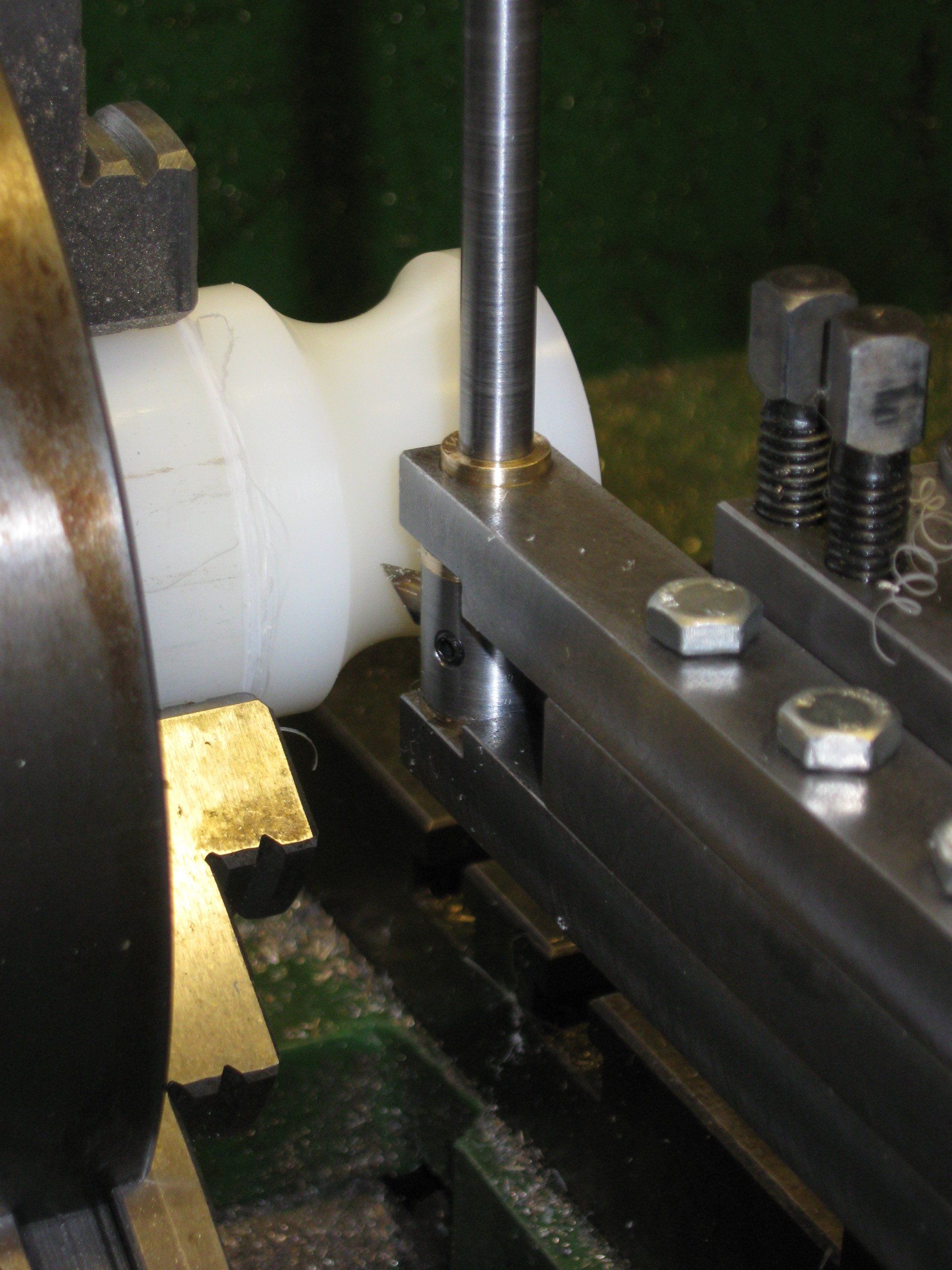

Next I needed to design and build a tool that would allow me to turn concave radii on the lathe. Pictured undergoing a trial run on some acetal.

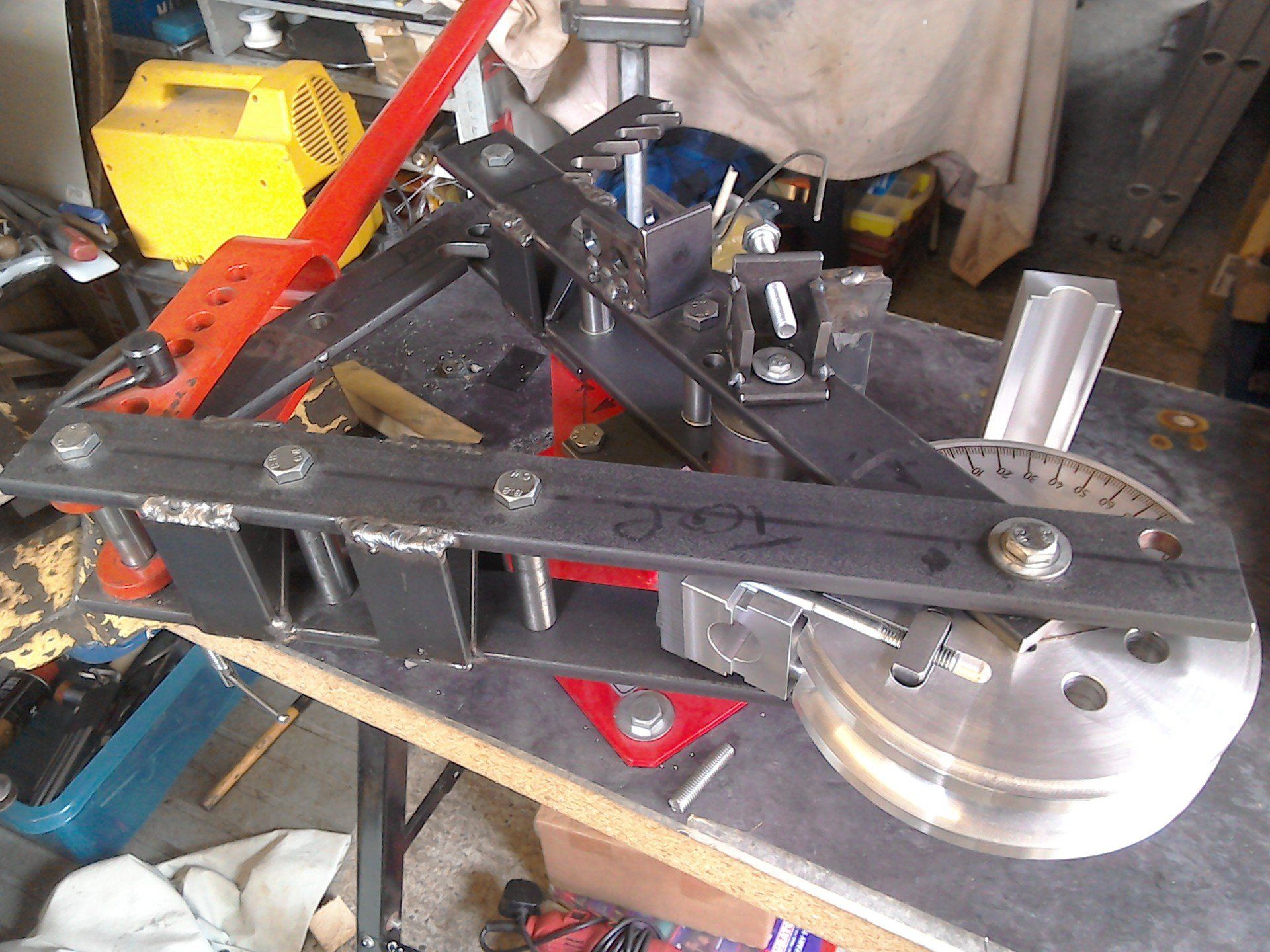

That rather rough and ready contraption is the finished tube bender. I certainly can't claim that this worked successfully first time. Part of its odd looks are because bits were added over time; to stop the bender flexing, to stop the tube slipping, to adjust the pressure on the tube etc. etc. Eventually, I started to be able to produce reasonable quality bends.

Lots of bits of tube were used testing the bender, before some acceptable bends were achieved - at least I had lots of tube to use for welding practise.

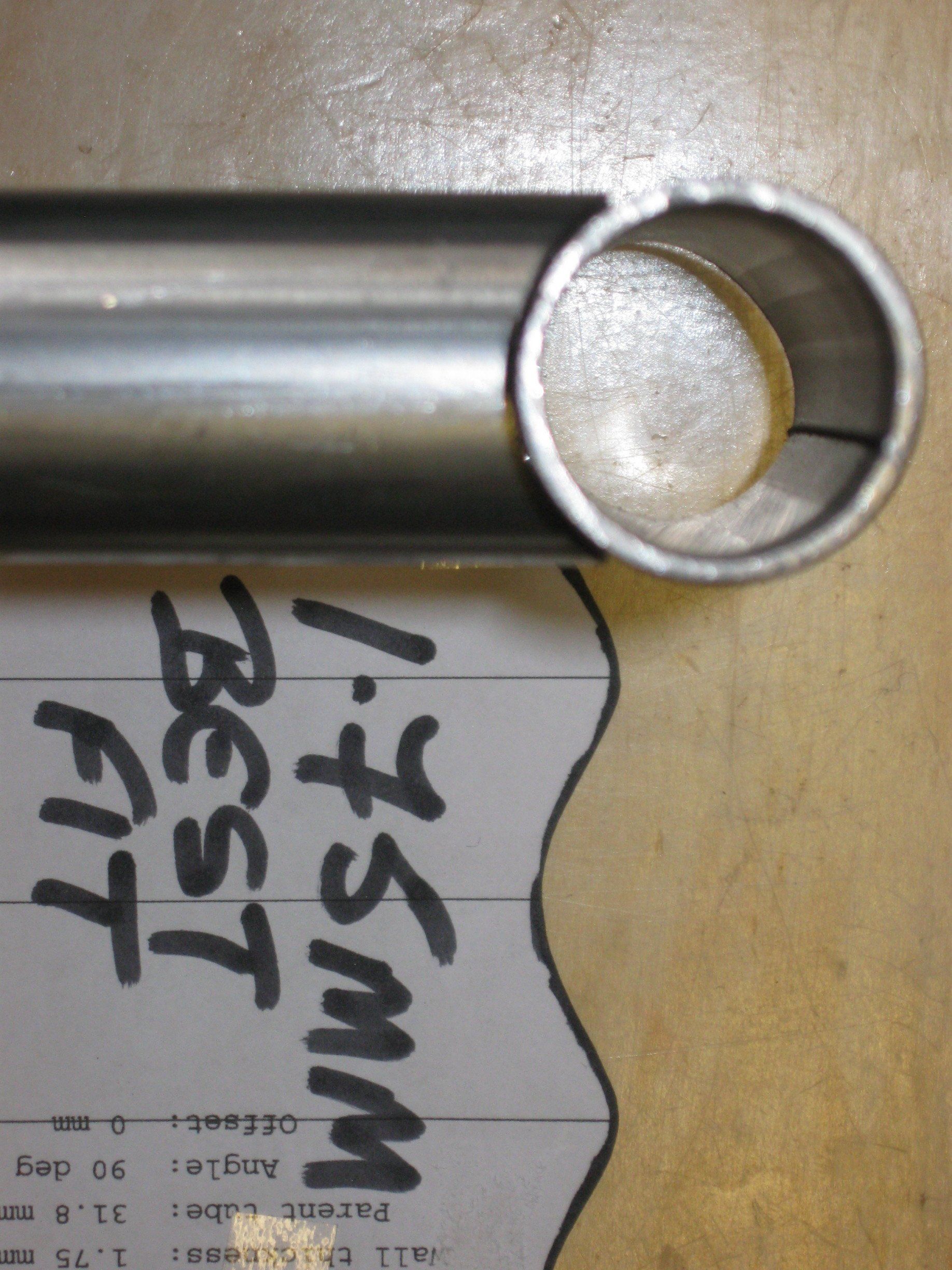

Practising notching tubes (and then welding them together). There are several online notching / mitring / coping calculators available online. I used one from the Metalgeek website - see resources section for link.