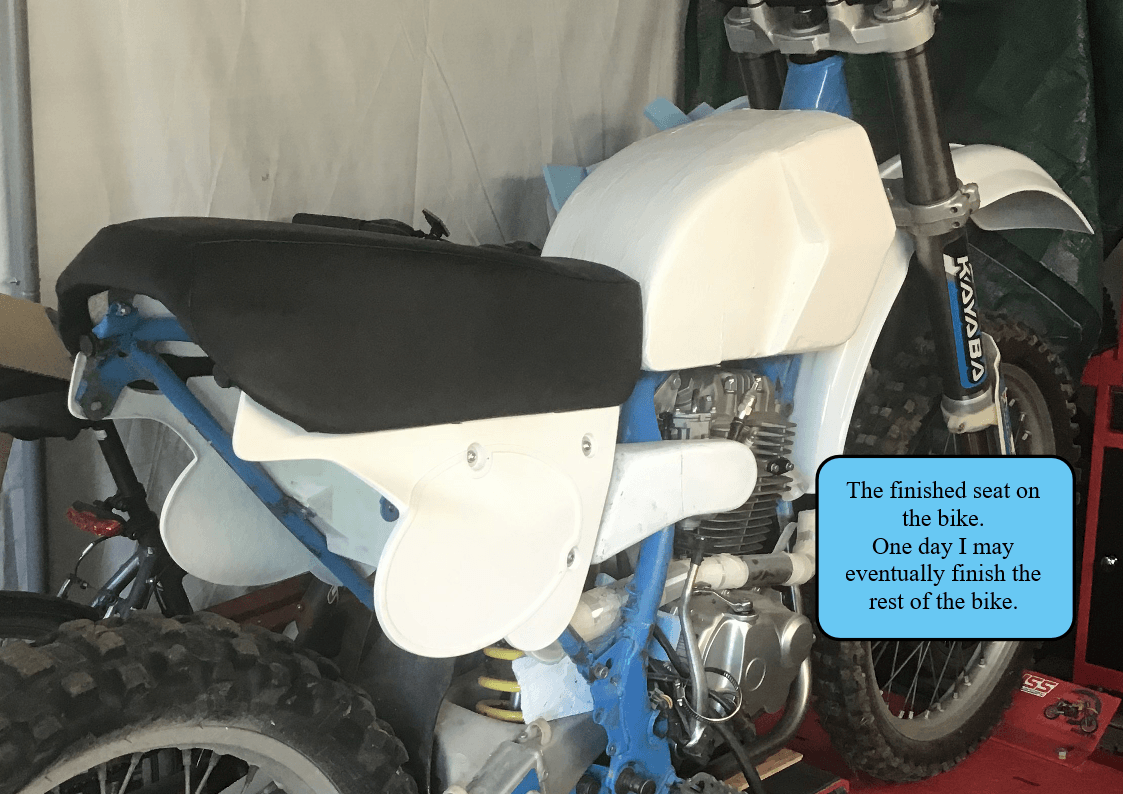

This time, my inept seat making skills are pressed into service to make a seat for the (long running!) dirt bike project…

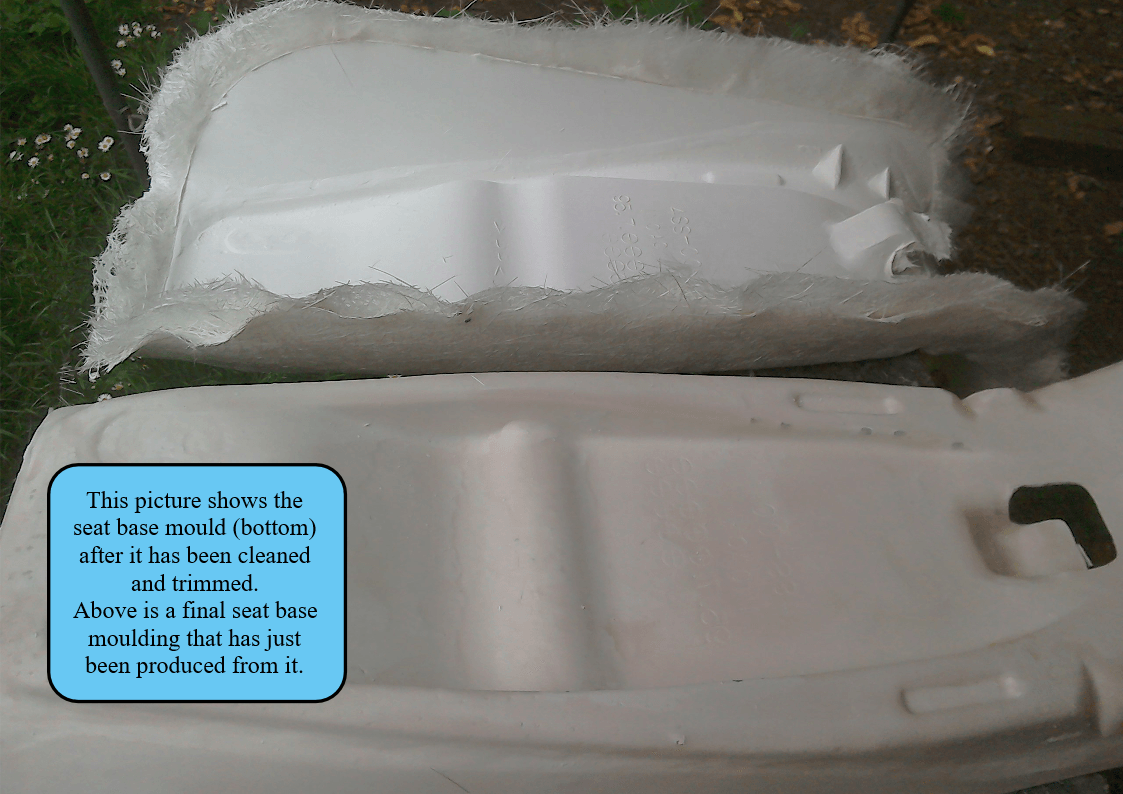

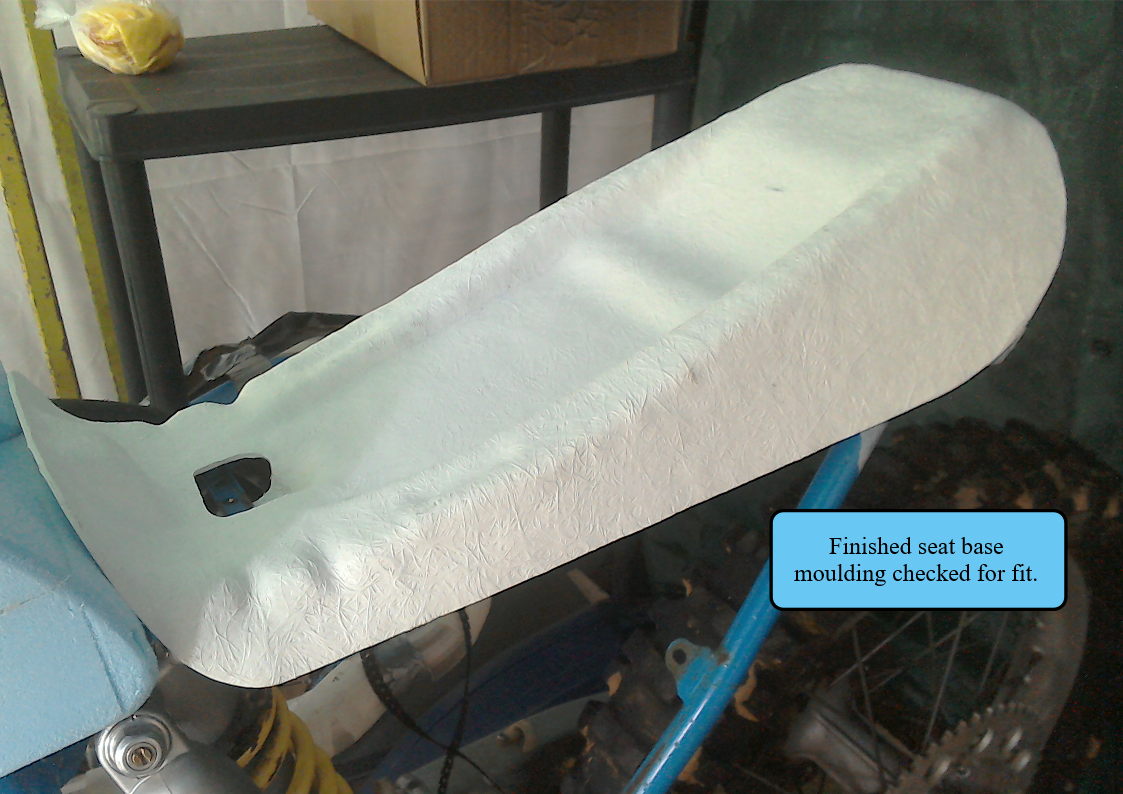

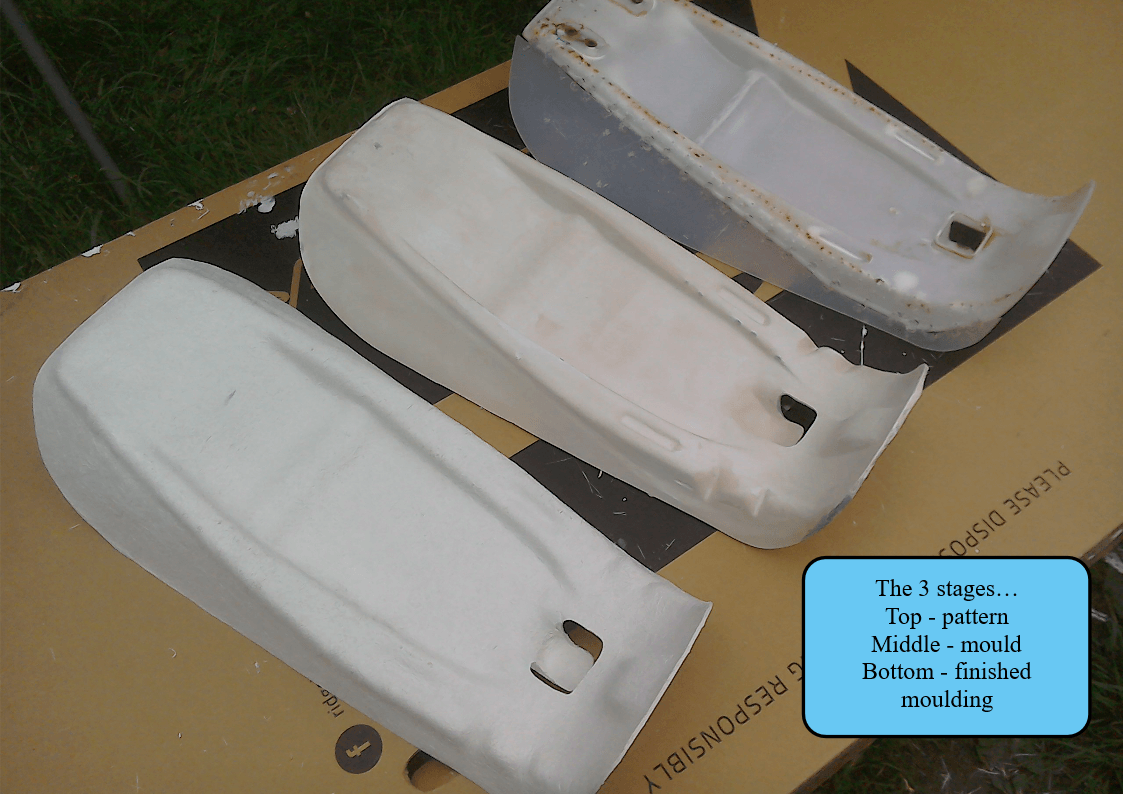

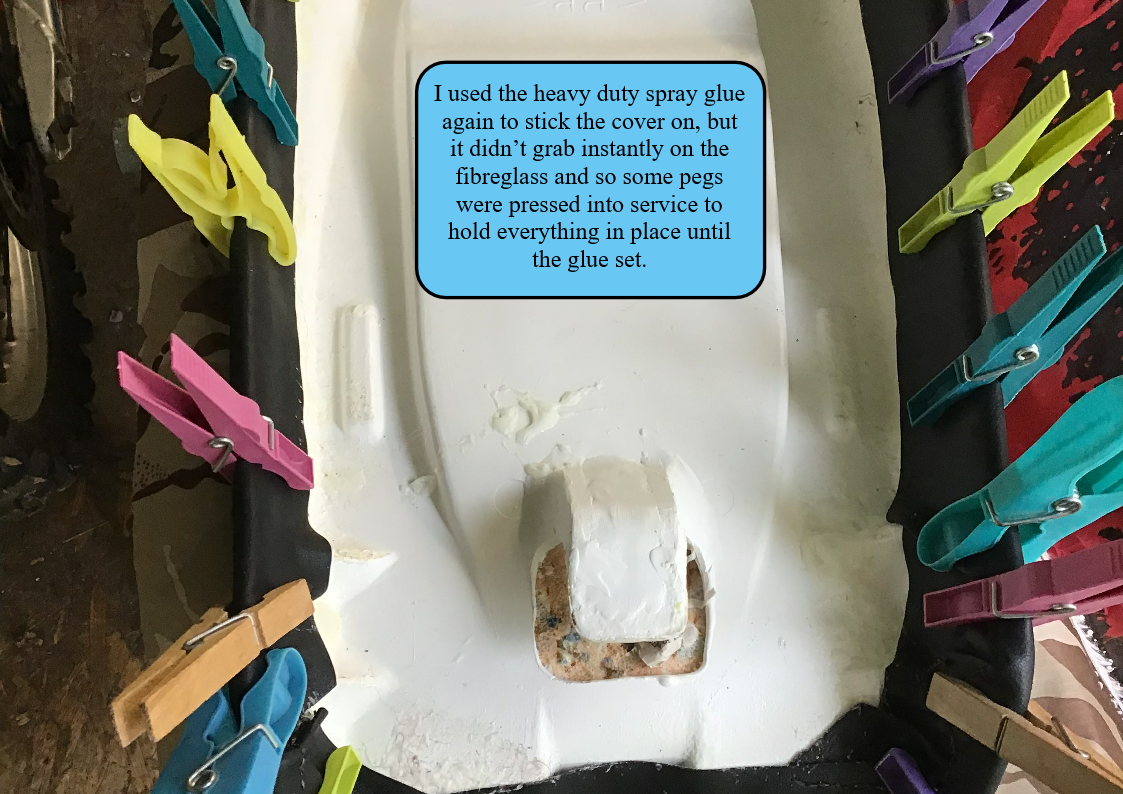

The seat base for this project is fibreglass meaning that the cover will have to be glued in place, a prospect that worries me somewhat as I only get one shot at it. At least with staples into polypropylene, you can pull them out and have another go. Making the seat base itself was a little long winded, requiring a pattern to be made from the original Yamaha base together with some added plastic wings. The wings were held in place using a cheap EBAY plastic stapler, which looked rather a rudimentary tool, but did firmly join the pieces together. There’s also a review of the stapler HERE. There are now cheaper staplers available from EBAY, but as I haven't tried one I can't comment on how well they work. This pattern was then used to produce a mould and then eventually a moulding of the finished seat base. There are some photos of this process below.

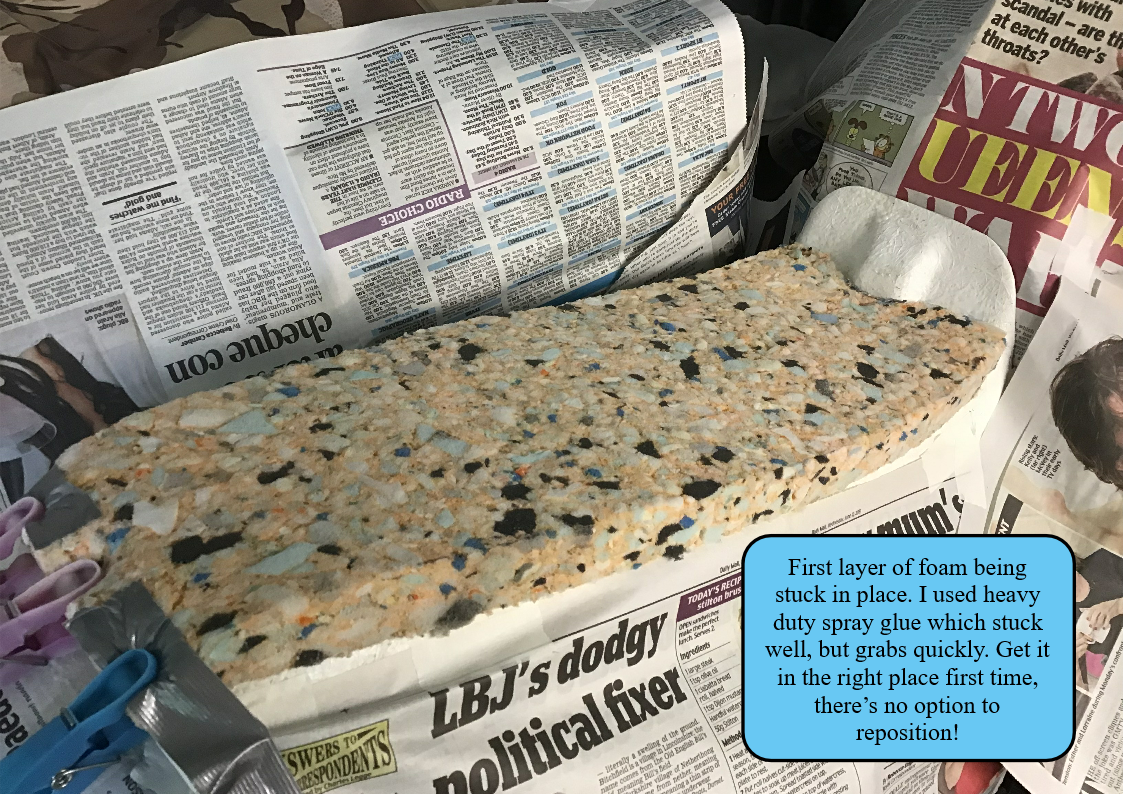

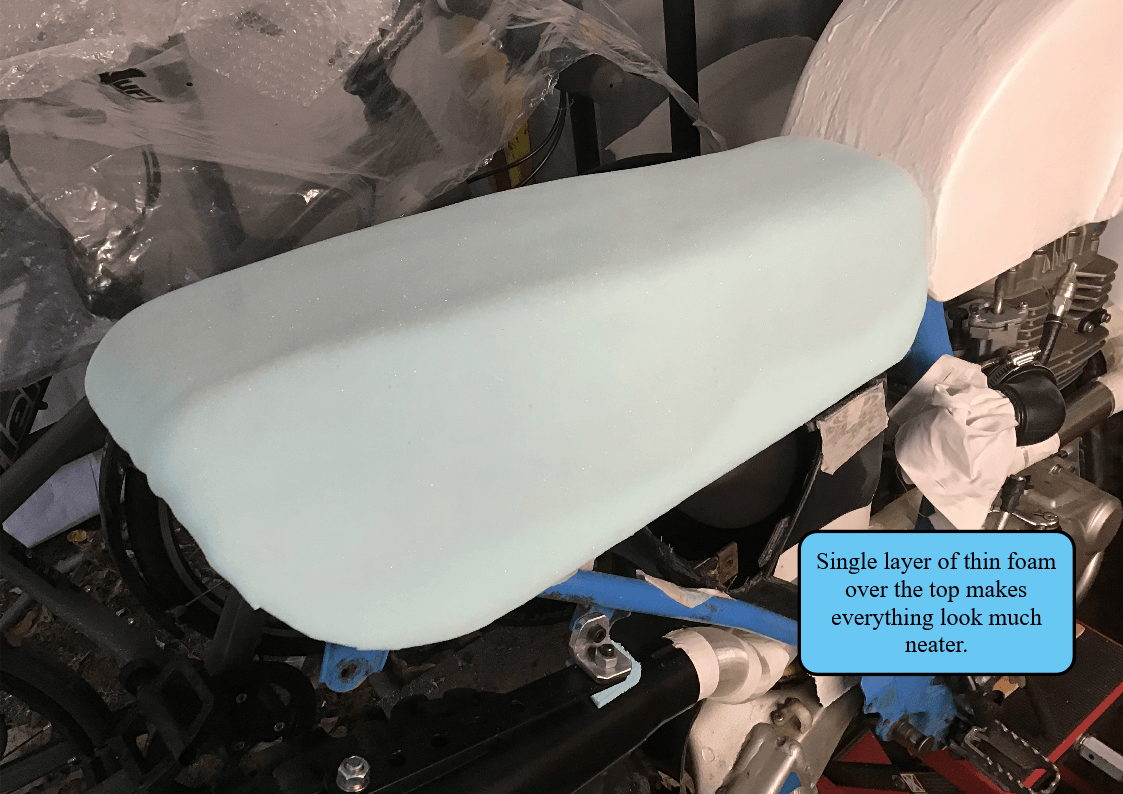

Now I needed to add (and shape) the seat foam. Once again, the bulk of the seat is made from cheap reconstituted foam, but this time I’ve added a thin layer of foam over the top to smooth things off.The best tools that I had to hand to shape the foam with were a hacksaw blade to remove bulk, and an angle grinder with a standard grinding disc to smooth and shape. A flap disc on and angle grinder is usually my favourite grinding / shaping tool but in this case it just grabbed and tore the foam. You may have to do some experimenting to find what works for you.

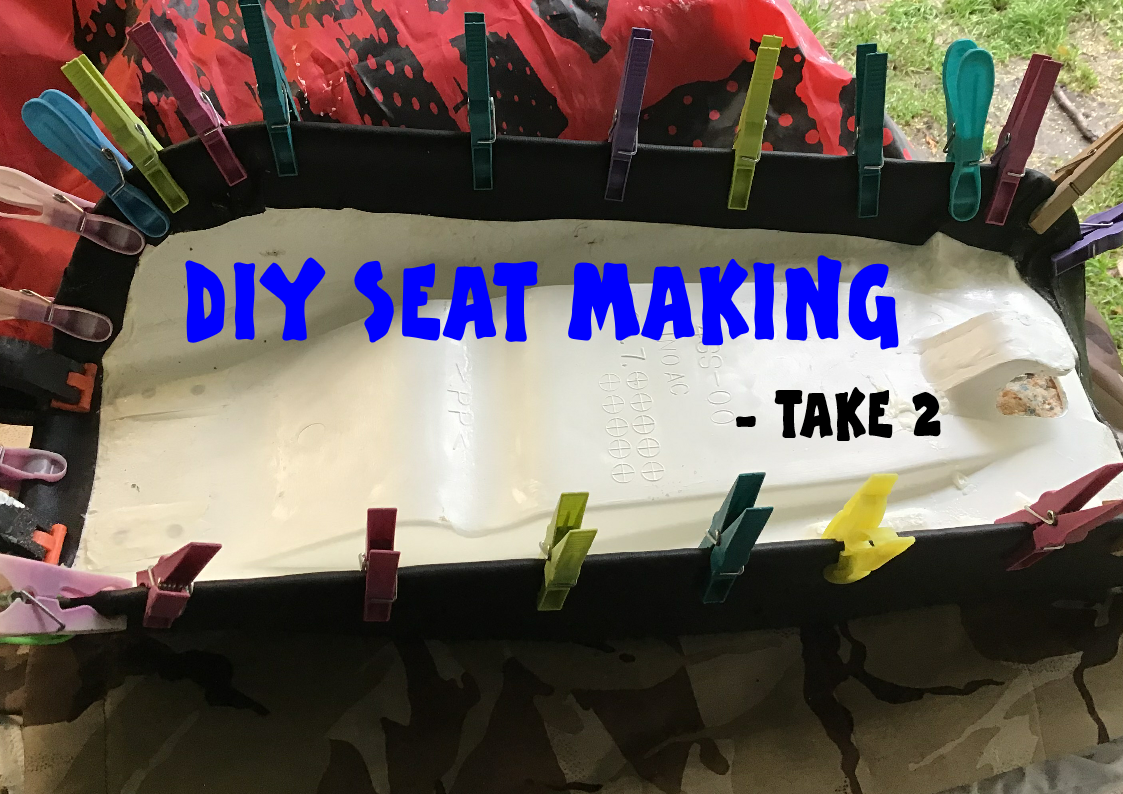

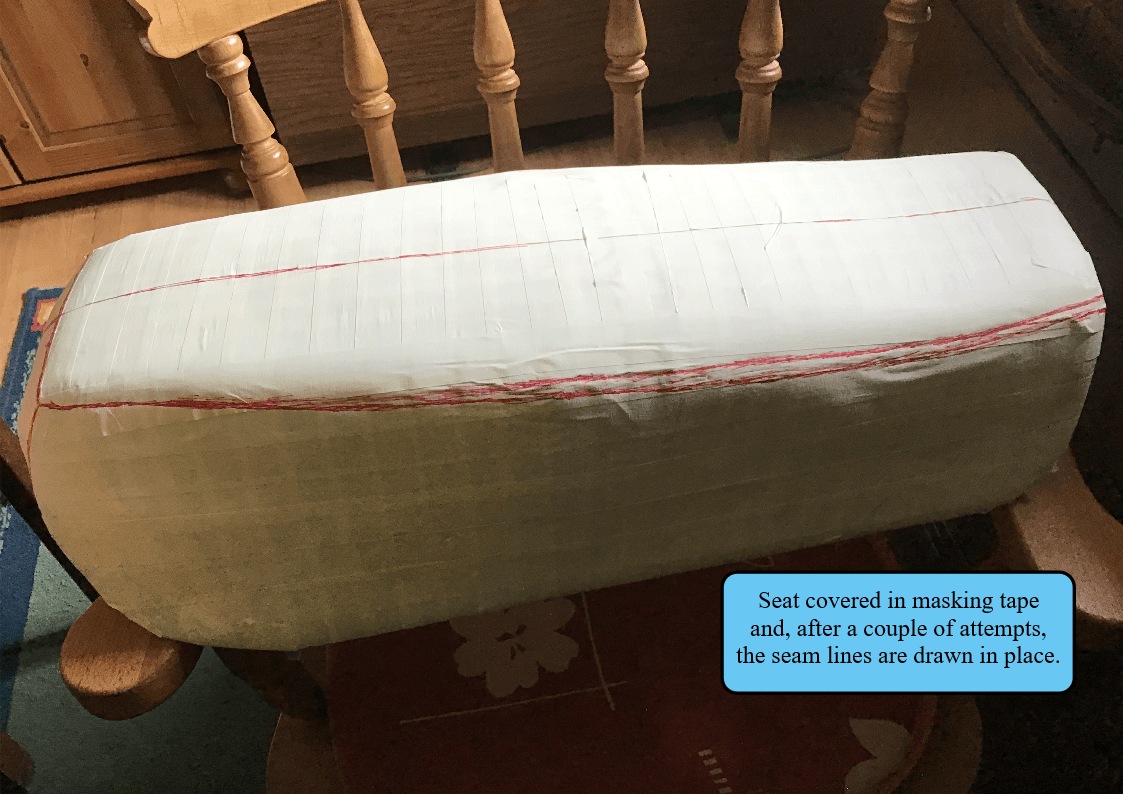

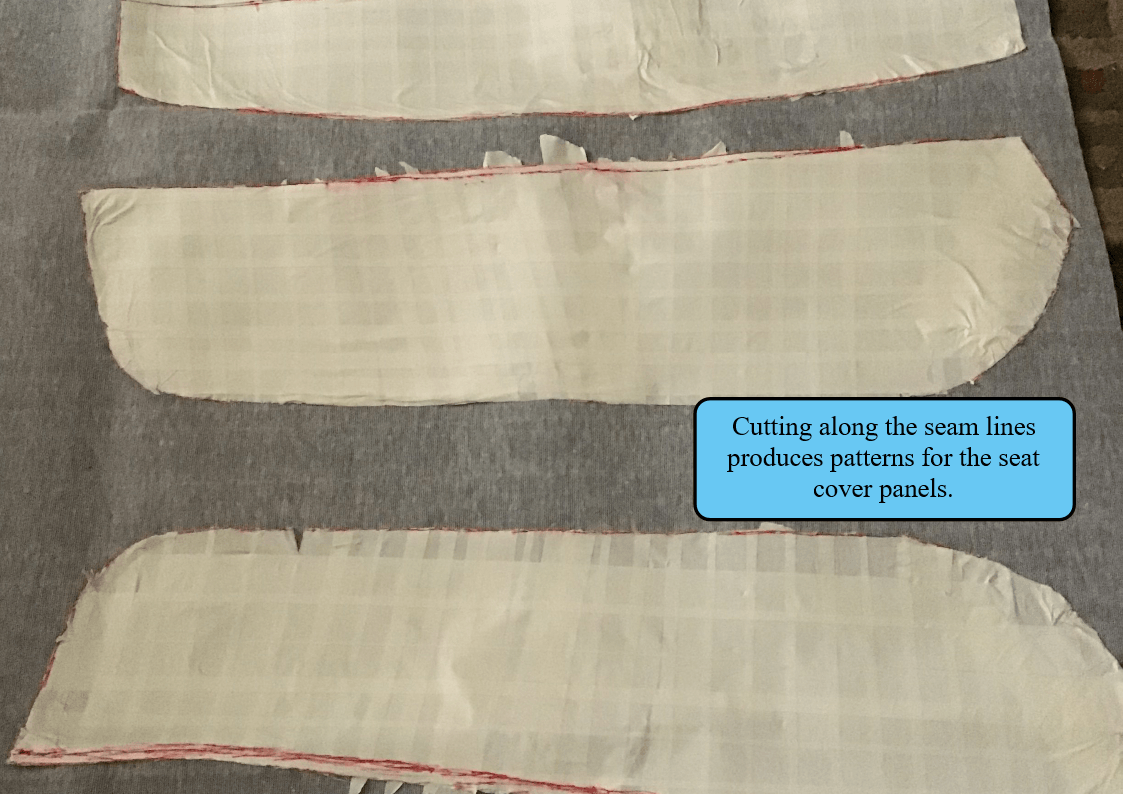

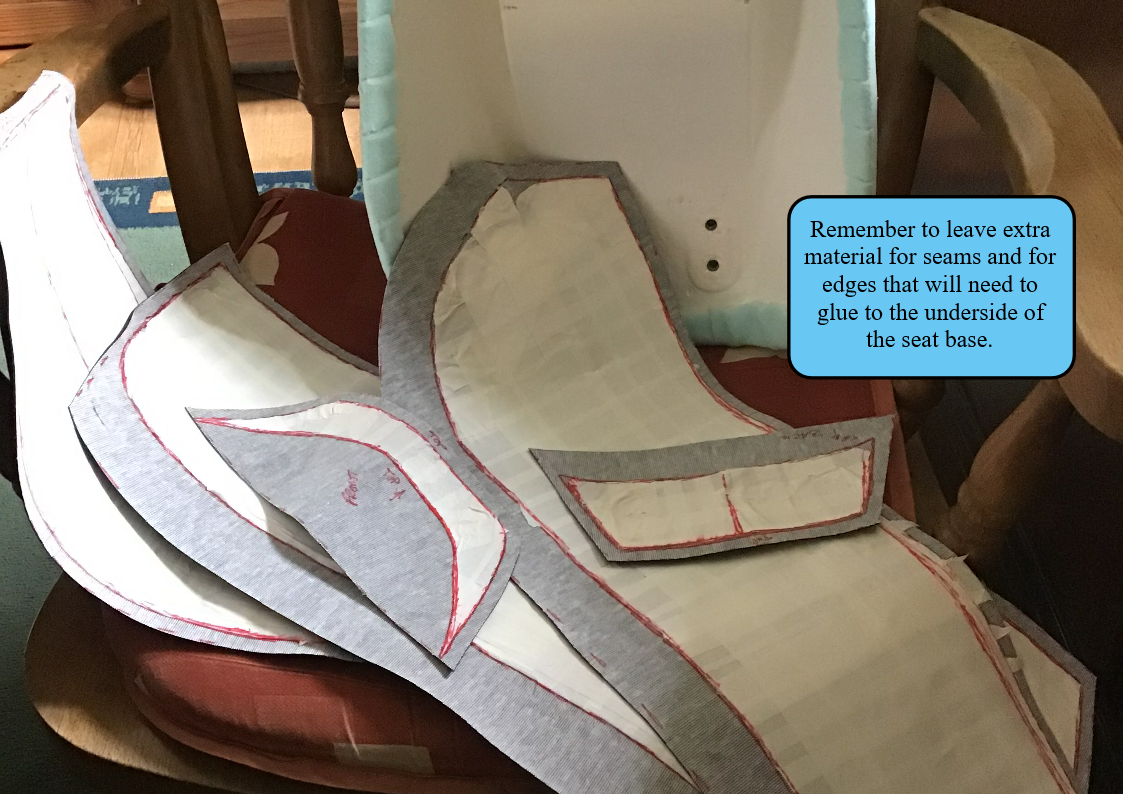

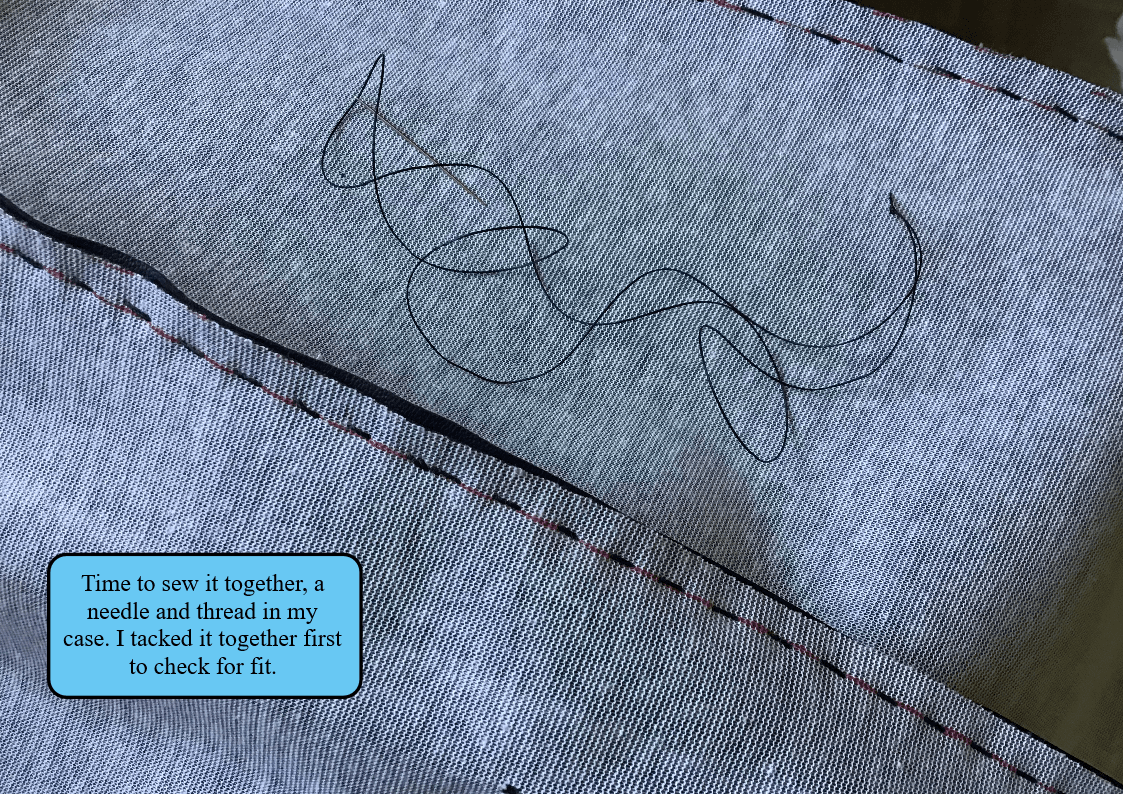

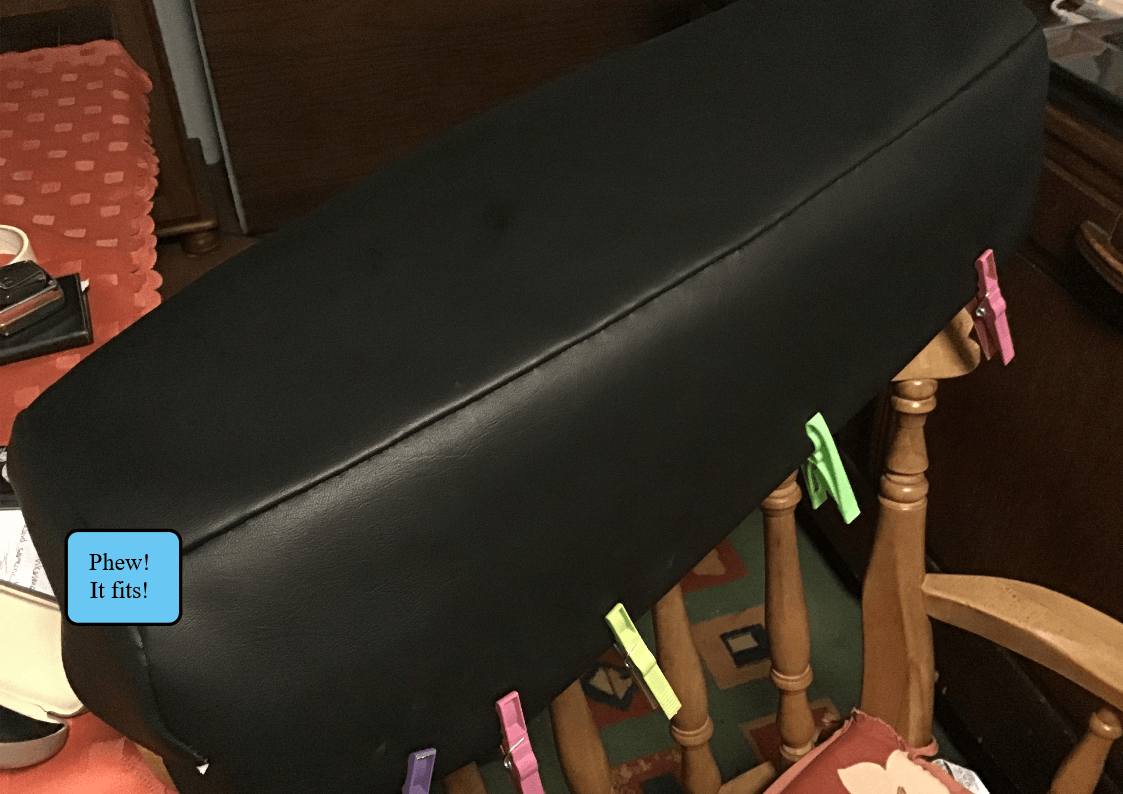

Finally, the tricky seat cover making stage. One solution to making a pattern for the cover (found on youtube) was to cover the seat in masking tape and then mark out where the seams need to go. Carefully cutting along the seam lines should then leave you with templates for all the pieces of the cover. Remember to leave a little extra where the seams are to be sewn together and a lot more extra where the cover needs to fold under and glue to the seat base.

See our other attempt at seat making HERE

There's also more detail on making the seat base etc. in our 2019 Monday Articles