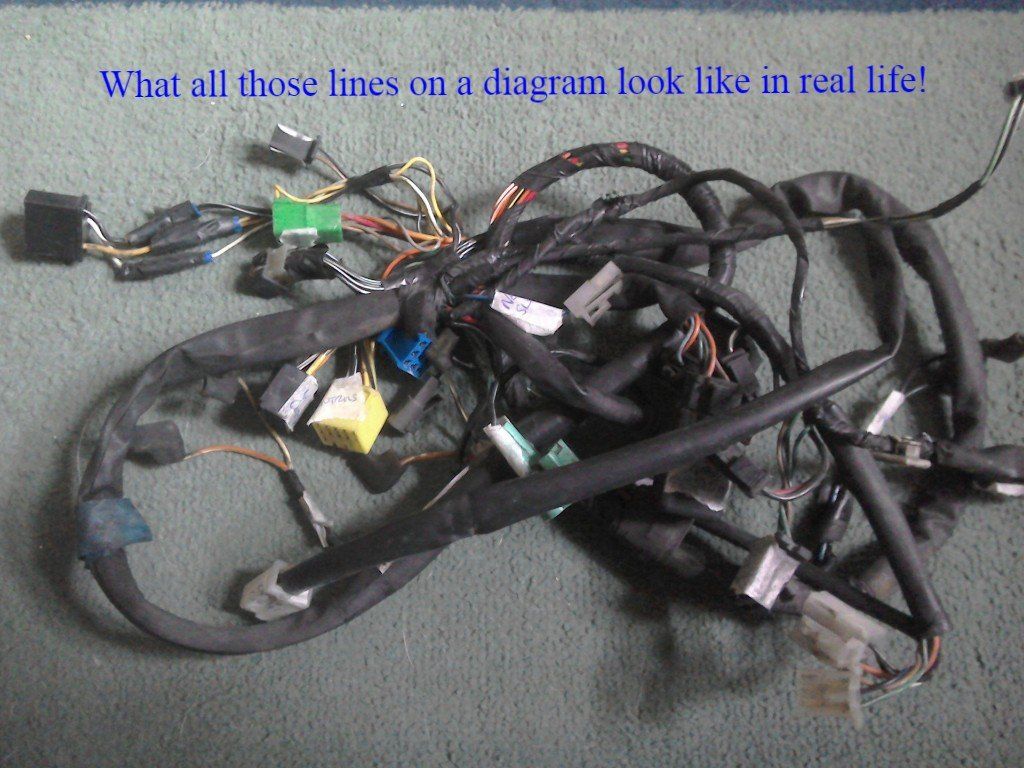

Wiring and electrics. They seem to strike fear into the heart of even the most seasoned home mechanic. I think we’re all probably more confident with the mechanical aspect of bikes. Usually you can physically see what is broken, what is worn, what isn’t moving when it should and what is moving when it shouldn’t! You can’t actually see all those little electrons that should be careering around the wiring loom; making spark plugs spark, light bulbs light and starter motors turn.

So, I’m going to attempt a series of articles about the electrical systems on your bike. A few caveats before I start: 1) Electrical systems vary greatly from bike to bike (and even between different model versions of the same bike) and so this will only be a generalised overview. 2) I only work on bikes from the late 80s to 90s, so if you have a Lucas magneto (old bike stuff) or fuel injection (modern bike stuff) I will just look blankly at you. 3) Most of my knowledge of electronics/ electricity was learnt at college 20+ years ago and promptly forgotten after the exam! If I make errors, please forgive me and I hope that some readers with greater, more up to date knowledge may contribute to future articles.

Having now confessed to my somewhat sketchy knowledge of the subject, you may wonder how any article written by me is going to be of any use to you. Well, what I hope to be able to do is to stop the blind panic that you may experience when first looking at a wiring diagram and get you to use the same powers of reason, logic and deduction that you have and use when confronted with a mechanical problem.

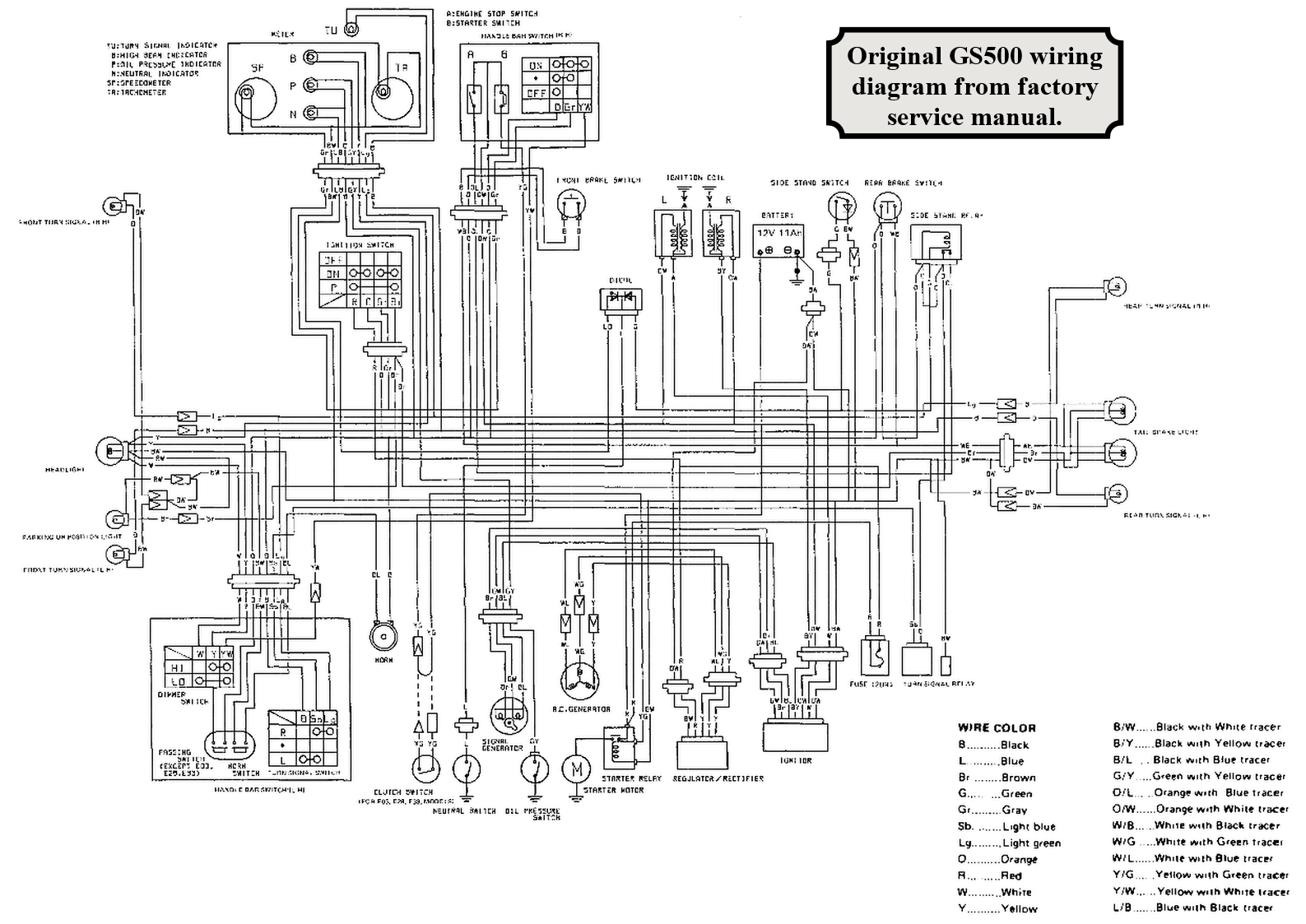

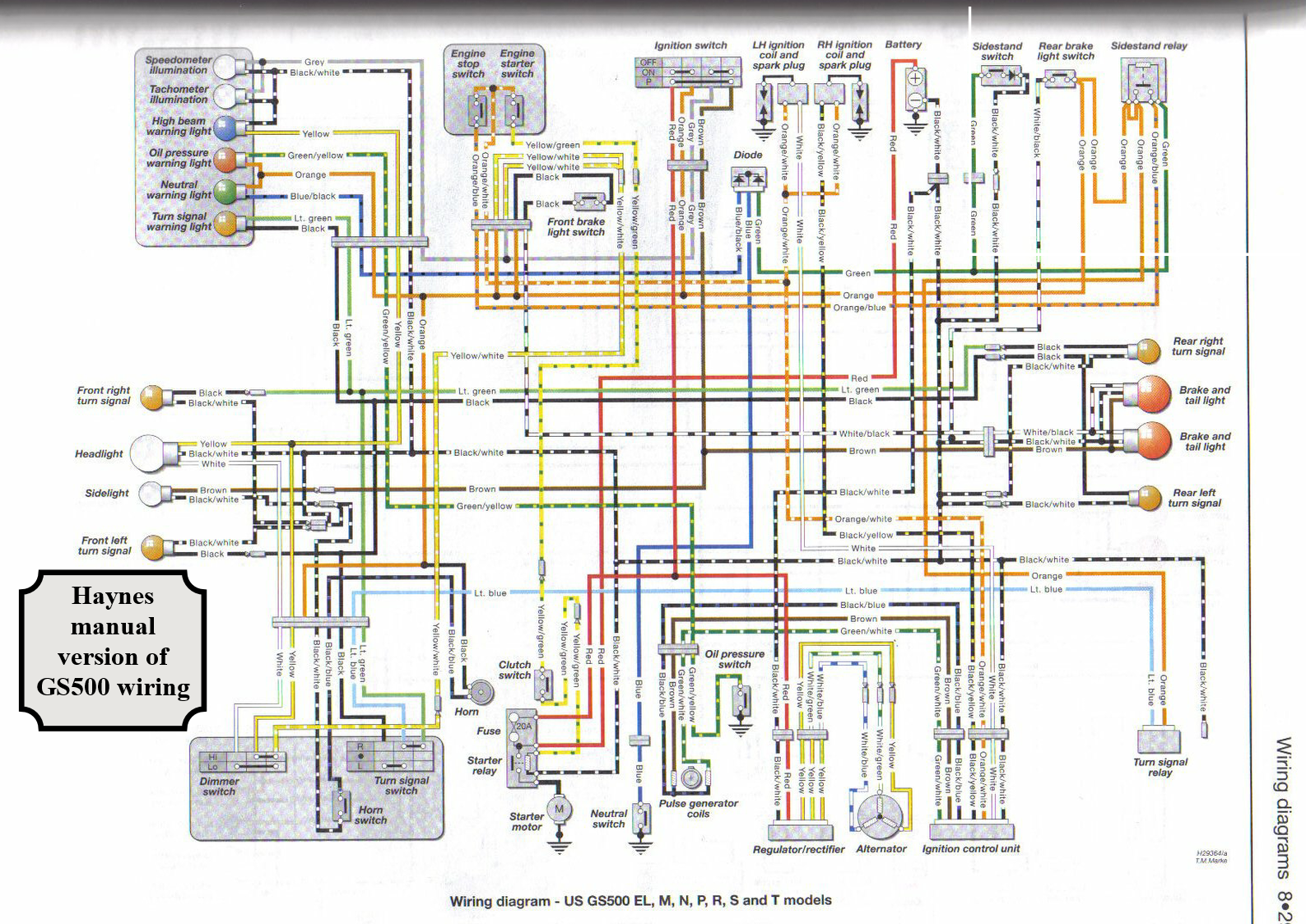

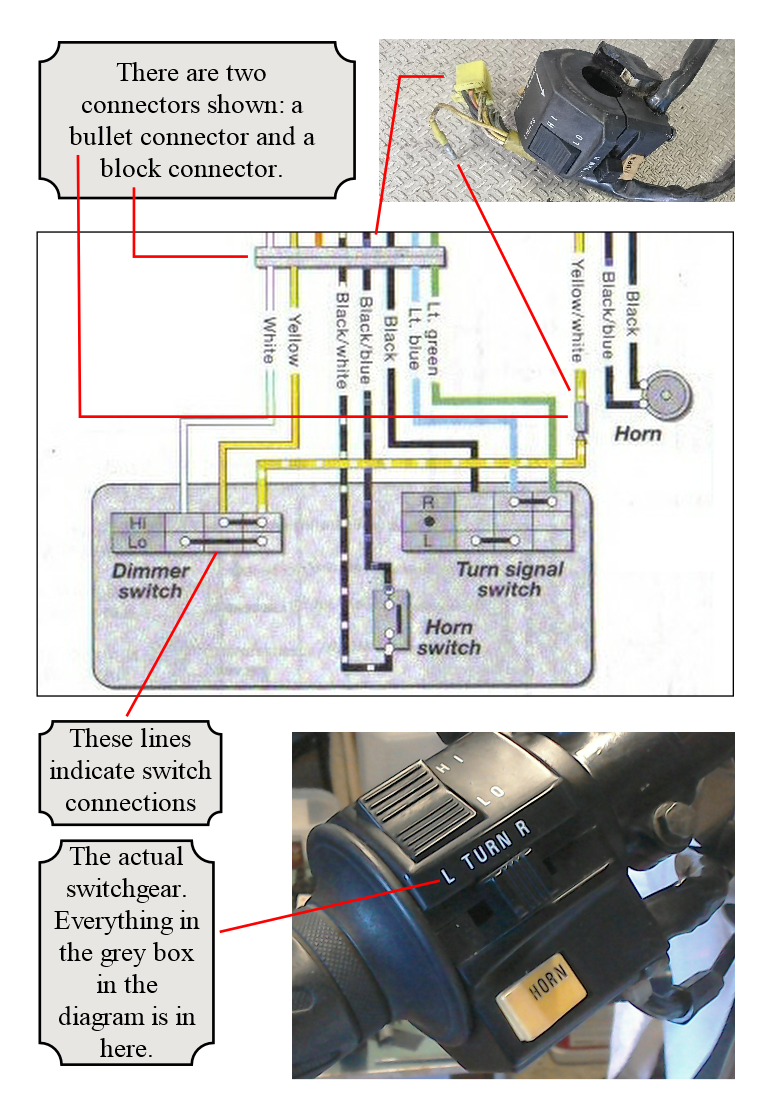

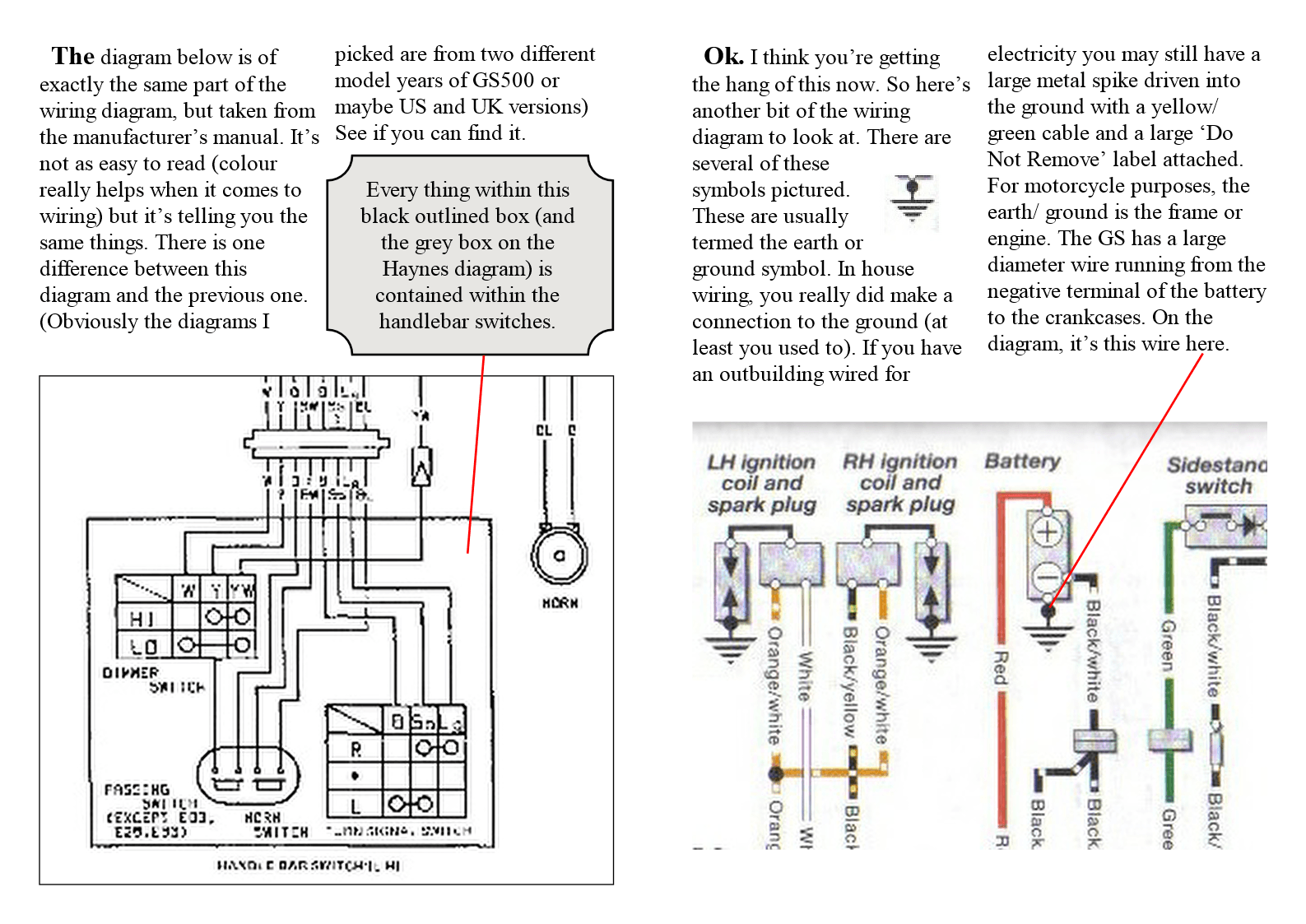

In this issue, we’re going to look at wiring diagrams (so if you want to have a little panic, scroll down now to see a typical wiring diagram). Now take a deep breath and relax. We’re going to break the diagram down into smaller bits and then it won’t be so scary. The following pages show two wiring diagrams for a GS500. The first one is from Suzuki’s own service manual, the second a Haynes manual version. I suspect all of us find the coloured version a little more user friendly, but essentially they both give us the same information. A Haynes manual is good for hints and tips to help you maintain your bike without special, factory tools, but you get far more detailed information from the factory manual. Factory manuals used to be very expensive (hence the popularity of the Haynes version) but thanks to the internet you can now usually find a cheap (or free) pdf copy.

In future issues we will be looking at different parts of the electrical system using diagrams and descriptions from the factory manual - information that the Haynes version simply doesn’t contain.